銅線IMC覆蓋率分析系統

應用介紹

INTRODUCTION >> IMC Coverage半導體封裝其內部接合方式,可分為打線接合(Wire Bonding, 又名銲線接合或引線鍵合)、捲帶式自動接合(Tape Automated Bonding, TAB)與覆晶接合(Flip Chip Die Bond)。其中,打線接合(Wire Bonding),是利用線徑15-50微米的金屬線材,將線材銲接在晶片(Chip)的鋁墊(Pad)與封裝基板的導腳(Finger)或其他電子元件的銲點上,做為晶片電性訊號與外部連接傳遞之橋樑,由於製程發展時間較長,相關設備與技術已趨於穩定成熟、成本低、佈線彈性高,是半導體應用最廣泛使用的積體電路封裝接合技術,在封裝製程中仍佔有很重要的應用地位。

打線接合(Wire Bonding)所使用之金屬材料主要有金線、銀線、銅線、鋁線等,其中鋁線、銅線主要用於中低階電路,貴金屬線在中高階產品之佔有率則超過80%。在過去幾年銲線所使用之金屬材料一直以金線為主流,由於「金」具備穩定性高、質軟、延展性佳等物理特性,被用於積體電路封裝之打線接合時,其良率、生產效率及線徑微細化等表現,皆相當不錯。然而近年來黃金價格一路上漲,使半導體封裝業者與IC設計業者在成本效益考量下,轉而積極投入「銅」打線技術的研發,逐漸以銅線取代金線,除了銅線的價格比金線低廉,銅線也具有優異的導電性、導熱性與高延展及斷裂強度,接合的阻抗也比金線小,在相同線徑的條件下,可以承載比金線更大的電流量,散熱速度也高於金線,可提高元件的冷卻效率,是具有發展性的金線替代材料。

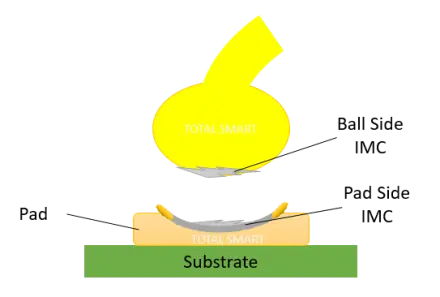

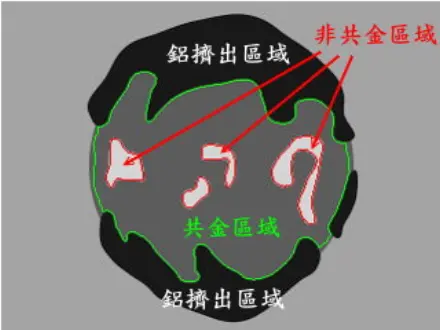

對於銅線銲接製程來說,緊密的銅-鋁接觸是產生良好介面金屬共化物(Inter-Metallic Compound, IMC,又稱介金屬、金屬化合物、金屬互化物)的重要條件,它可以提供晶片與外部接點鍵合成穩定且堅固的導電通路;反之,IMC覆蓋面積或IMC覆蓋率(IMC Coverage)不佳,或者鋁擠出過大,也有可能造成水氣由此間隙侵入,導致IMC Crack的現象發生,嚴重的話會可能發生銅球脫落問題,進而影響產品良率。介面金屬化合物(Inter-Metallic Compound, IMC)是兩種以上金屬元素以「固定比例」所形成的化合物,是一種「化學反應」後的結果,屬於純物質,不是合金(Alloy)也不是純金屬,但也有人把IMC歸類為合金(Alloy)的一種。

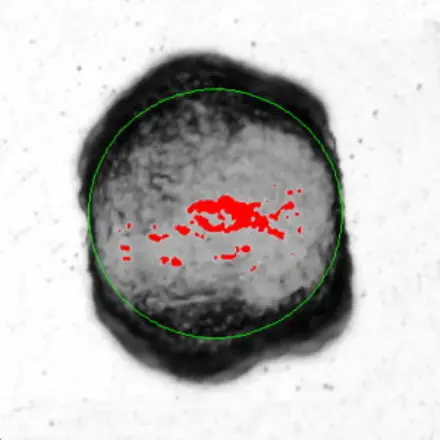

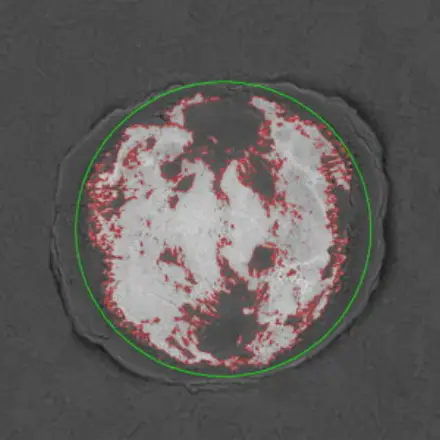

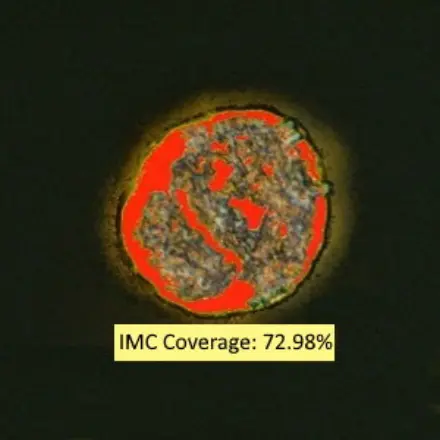

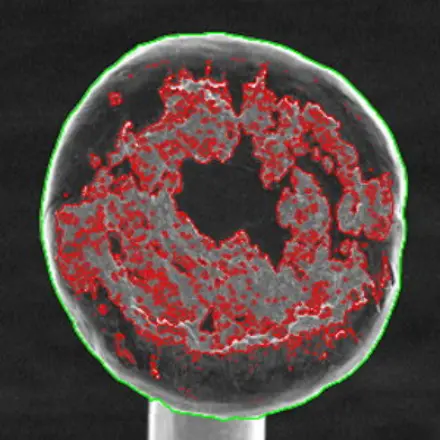

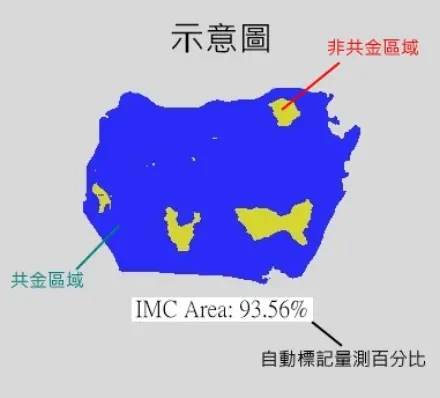

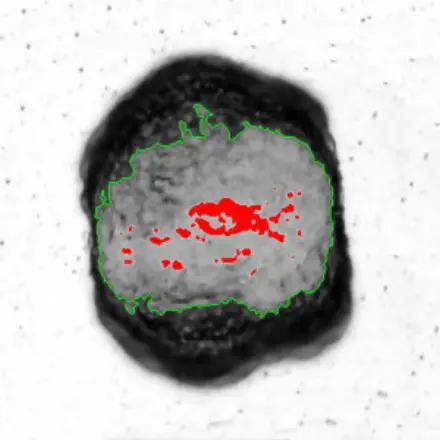

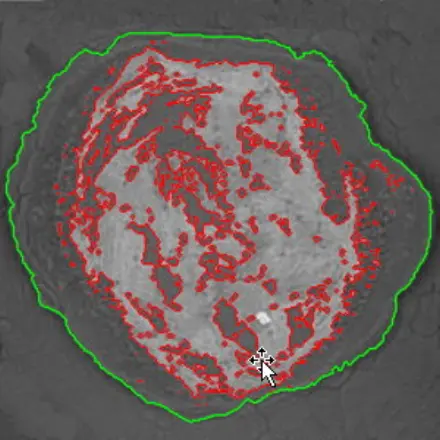

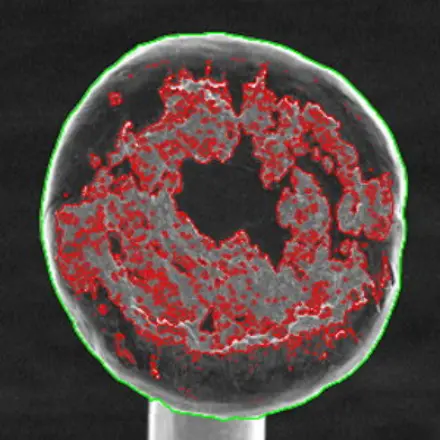

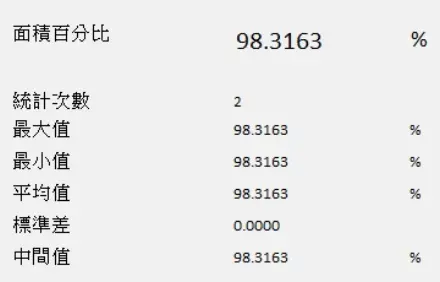

銅線IMC覆蓋率分析系統應用於打線接合(Wire Bonding)製程,不論是光學顯微鏡(Optical Microscope, OM)或掃瞄式電子式顯微鏡(Scanning Electron Microscope, SEM)取像之IMC照片,即Ball Side IMC與Pad Side IMC,皆提供完整的IMC Coverage自動化分析解決方案,亦可依照分析需求設定銲線線寬、銲嘴直徑或鋁擠型輪廓做為分析選取範圍,準確的量化分析出介金屬覆蓋率(IMC Coverage)、介金屬覆蓋面積(IMC Coverage Area)及介金屬長度(IMC X/Y Length)等品質管制數據,也可直接量測鋁擠出X和Y方向的長度,軟體操作簡單,只需幾個簡單的操作步驟,即可快速選取IMC共金材料的面積,同時導出IMC共金與Non-IMC非共金之面積百分比,分析完成後還可依需求匯出Excel分析報告或上拋分析結果至資料庫,絕對是封裝打線製程品質量化分析的最佳利器,亦是驗證產品可靠度與調整製程參數的必備工具。

關鍵字:IMC IMC Coverage Wire Bonding Parameter 介金屬 介金屬覆蓋率 銲線參數

分析功能

ANALYSIS FEATURES >> IMC Coverage鋁擠形

銲嘴直徑、銲球直徑

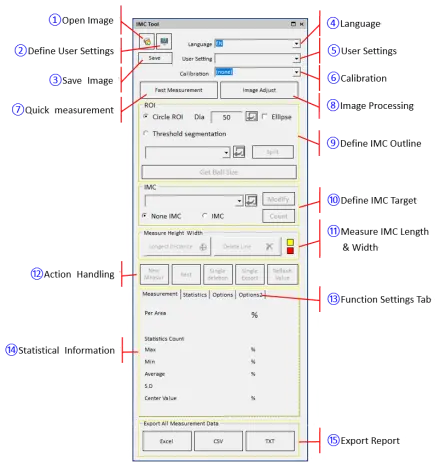

IMC 覆蓋率分析功能介面

IMC Coverage Analysis Function & User Interface

操作界面語系支援英文、繁體中文和簡體中文。

IMC覆蓋率分析

IMC Coverage Analysis

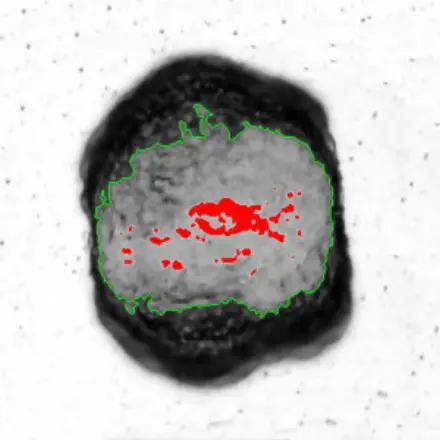

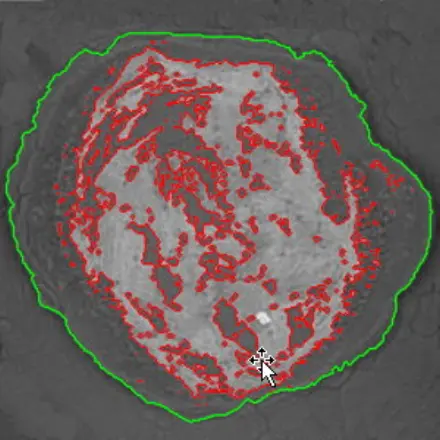

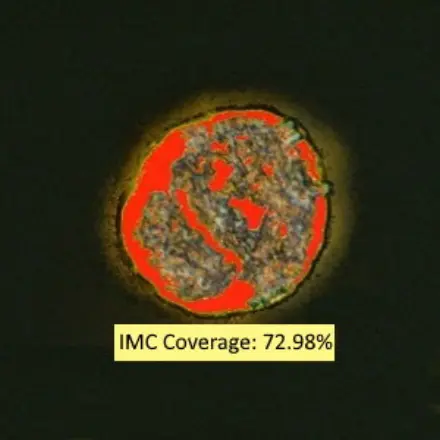

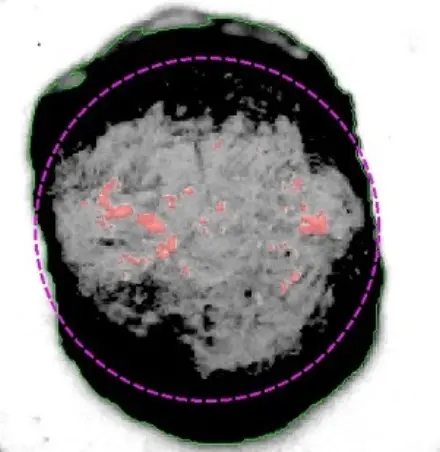

IMC分析用於評估打線焊接材料中的介金屬化合物(Intermetallic Compound, IMC)之覆蓋率,透過演算法強化介金屬分佈區域影像,再透過影像處理與影像分析技術對其形態和分布進行量化與分析,可以提供客觀且可靠的製程量測數據。

IMC IMC Coverage 介金屬覆蓋率

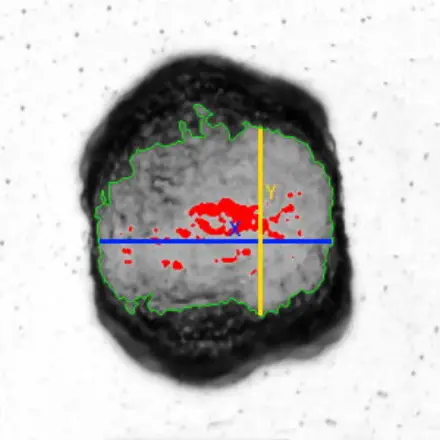

IMC X/Y長度量測

IMC X/Y Length Measurement

IMC X/Y長度量測,針對介金屬(Intermetallic Compound, IMC)所覆蓋分佈區域,透過水平與垂直長度量測,可準確計算 IMC 層的範圍,適用於打線銲接界面與材料接合的評估。

IMC X/Y Length

多樣化量測參數

A Variety of IMC Measurement Parameters

內建多種業界常用的IMC 量測模式與參數設定,可根據OM取得影像針對不同應用需求進行最佳化分析,提高測試效率。

IMC Parameters

SEM與OM影像皆可分析

Both SEM & OM Images Are Compatible with IMC Analysis

不論是掃描式電子顯微鏡(SEM)或光學顯微鏡(OM)所拍的IMC照片,只要簡單切換分析模式,就可以直接進行 IMC 量測,不論是Ball Side或Pad Side,皆支援IMC Coverage 分析。

IMC Coverage Analysis

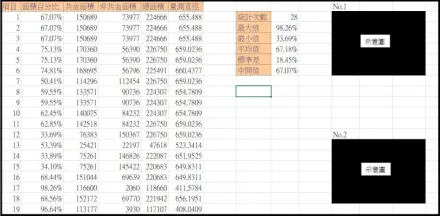

多筆量測與統計分析

IMC Multiple Measurement and Statistical Analysis

支援多筆 IMC 測試數據連續量測,並自動統計厚度、分布範圍、標準差等數值,讓數據結果一目瞭然。

IMC Coverage Statistics

適用各類銲線材料

Applicable to IMC Analysis of Various Bonding Wire Materials

支援金線、銀線、銅線等多種銲線材料,適用於各式積體電路封裝打線接合之介金屬覆蓋率分析,如有特殊需求,亦可提供客製化分析服務。

Wire Bonding

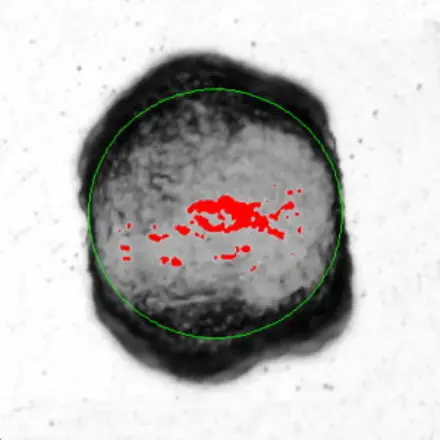

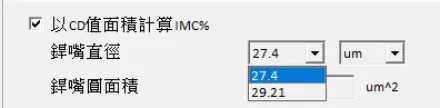

可依銲嘴直徑量測 IMC Coverage

IMC Coverage Measured Based On Welding Nozzle Diameter

針對打線製程所使用的銲線材料之延展性及物理特性需求,IMC Coverage的量測參數可選擇依銲嘴直徑或銲球直徑做為計算覆蓋率的基礎 ,分析數據可以更貼合實際需求,提升製程穩定性。

IMC Coverage Nozzle

快速量測、一鍵匯出

IMC Coverage One-Click Measurement and Export

一鍵自動將分析數據統計並匯出Excel,在匯出報告中一併將影像輸出同時標記IMC Coverage量測結果。

系統需求

SYSTEM REQUIREMENTS >> IMC Coverage- 作業系統:Windows 11 專業版 64 bit / Windows 10 專業版 64 bit

- CPU Intel® Core™ i7,3.0GHz (處理器建議16核心以上,最少4核心)

- RAM 16GB 或更高

- HDD 1TB 或更多 (可用空間20GB以上) / SSD 512GB 或更多 (可用空間20GB以上)

- Graphics Card NVIDIA GeForce RTX or above cards with 8GB graphics memory (選配)

- USB Port required to link licenses to a USB dongle.

- Microsoft Excel 2021(含)以上版本

- Add-in Module for Image-Pro